PP(POLYPROPYLENEE) ONE STEP FIBER PRODUCTION LINE

Polypropylene staple fibers offers superior feature due to its lowest specific gravity resulting into better relative coverage, high dimensional stability, excellent recovery properties namely elasticity and resiliency, low thermal conductivity, lowest static charge and its inertness to chemicals. The denier range of PP Fiber manufactured is 1.5D to 15Denier.

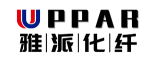

Process of PP One Step Fiber Production Line

Specifications of Virgin Polypropylene Staple Fiber

Deniers:- 1.5D to 70 Denier

Cut length:- 25,32,51,64,76,102 and 124 mm (as per customer requirement)

Tensile strength:- >3.5gm/Denier

Elongation:- >70%

Crimps:- 3 to 5 per cm

Shades:- All shades available

Applications of Virgin Polypropylene Staple Fiber

Spinning Yarns, Filter Fabrics, GeoTextile, Auto-mobiles floor carpet, thermal bonded fabrics, insulations, carpet, and non-woven carpet, building construction, RCC

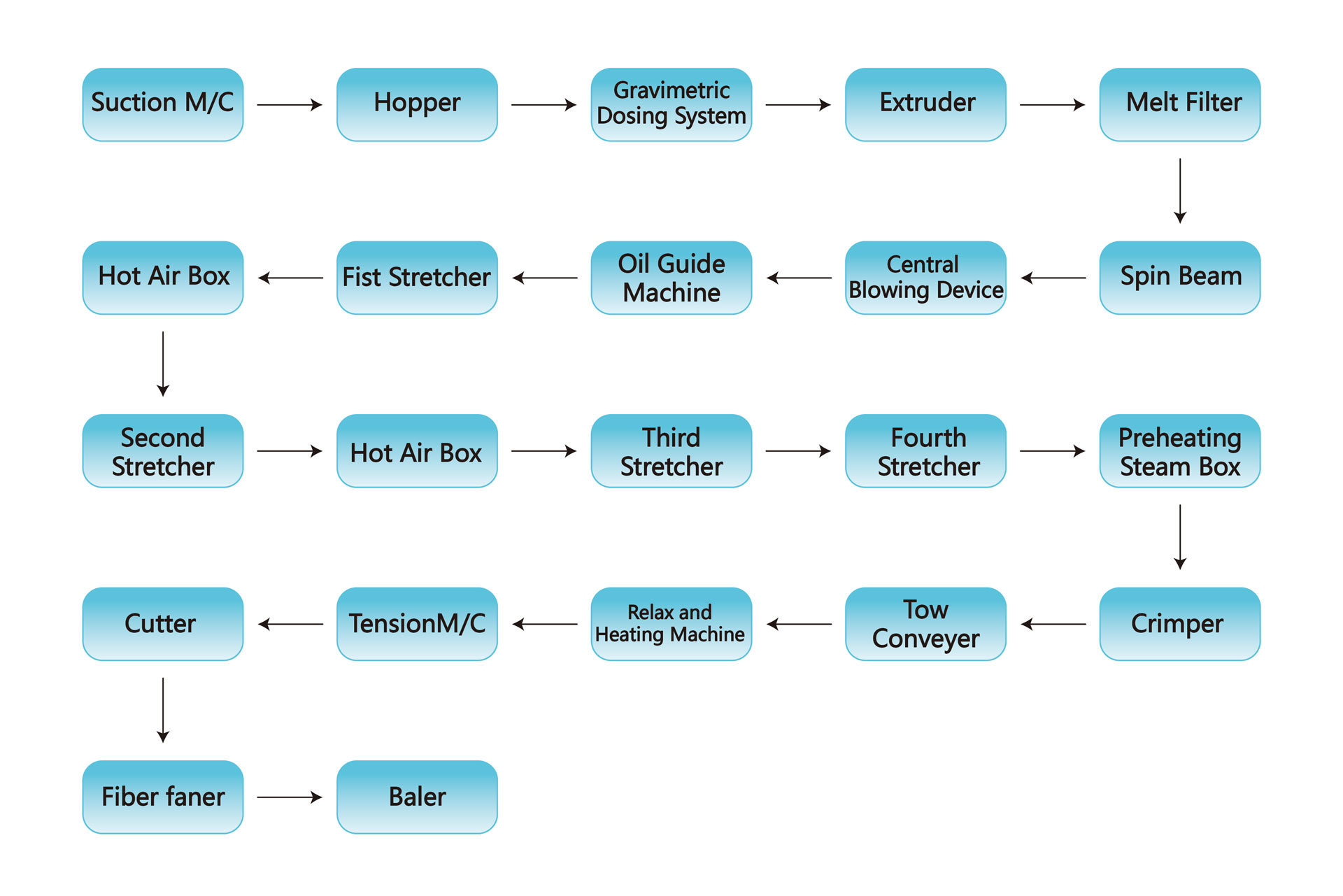

FACTORY DESIGN

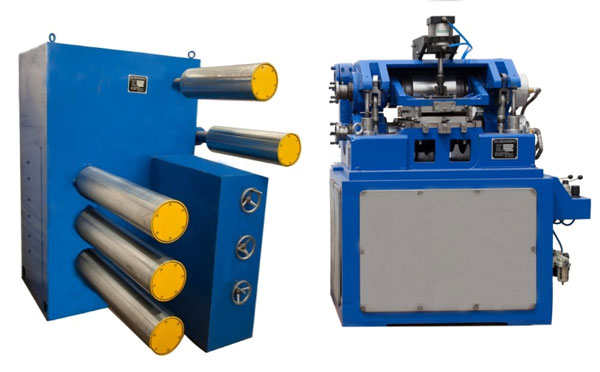

MAIN MACHINES OF PP ONE STEP FIBER PRODUCTION LINE

PP chips are fed into screw extruder by meaning of melted, mixing and filtering from hopper after being heated and dried

Specification: φ160,φ179,φ180,φ190,φ220

The melted PP will go through filter to remove the impurity.

1 Type: vertical, 2 groups of filtrating chambers, exchanging filtrating barrel continuously;

2 Heating Power: 15kw;

3 Heating Media: Thermal oil. Melt inlet pipe increase static mixer, inner of melt pipe is polished. Melt pipe and spin beam is connected by flange.

4 Control: Use pressure≥25MPa, inlet pressure electronic indication, and automatic control. Indication precision: 0.1MPa. Self-control precision: 0.3MPa.

The melt goes into spin beam in which specially-designed distribution piping system guarantees same dwell time and same pressure drop for the melt to reach each spinning position.

1.Distance between two adjacent positions: 1100mm

2.Installation of Spinneret: Install from below, dolly type spinneret installation bed

3.Heating Method: Dowtherm oil

4.Heating Power: 30KW

Composition of Spinning Part: Spin beam, distribution plate, spinneret, filter net;

Working Process: the certain temperature cold air from the AHU is blown by the frequency controlled blower to meet the blowing speed requirement of central blowing. The air goes through the central blowing to cool down fiber tow.

The cooled and solidified filaments are oiled and damped by oiling device to increase the cohesion of the yarn, to improve the antistatic property of the yarn, to reduce the friction between the yarn and the yarn, and also to reduce the friction between the yarn and equipment, and to improve the after-treatment property of the yarn.

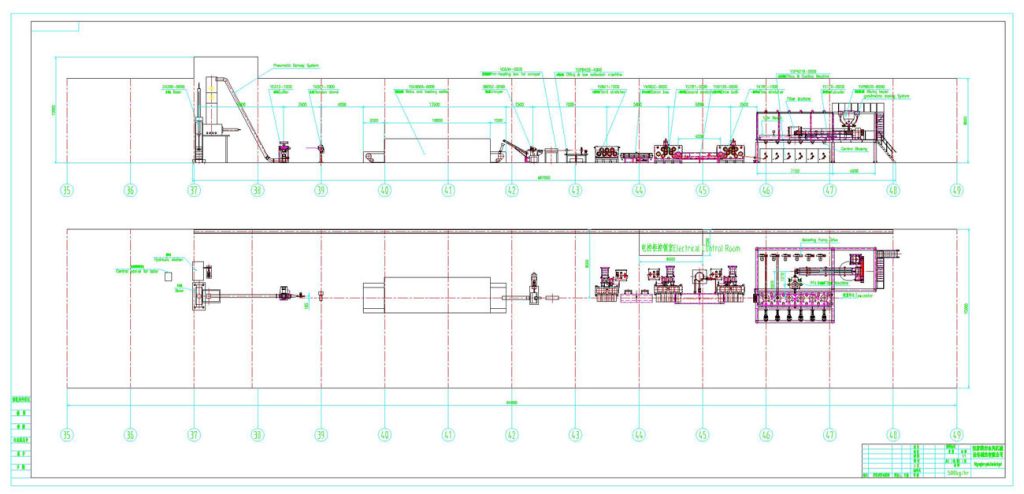

The range uses 2-stage drawing technology. The first drawing stage carries out between the first stretcher and the second stretcher. The temperature of Draw bath is about 60℃~80℃. The draft ratio of the first drawing stage is completed 80%~85%. The second drawing stage carries in Steam box chest between the second stretcher and the third stretcher. The draft ratio of the second drawing stage is completed 15%-20%.

After cooled and oiled, the tow sheets are sent into Tow stacker, 2 or 3 tow sheets are stacked into 1 tow sheet. The tilt angle of stacking rollers is adjustable for achieving stacking process. The width of the tow sheet and the quality of stacking is special important for crimping.

After stacking, the tow sheet is sent into Crimper through Tension control roller and Steam pre-heating box. The tow sheet is crimped through squeezing to assure the good performances of fiber in later process.

After crimping, the tows spread to chain board type conveying of Relaxing dryer. The tows are dried evenly by blowing of forced air and then cooled down below glass temperature.

After crimping, the tows spread to chain board type conveying of Relaxing dryer. The tows are dried evenly by blowing of forced air and then cooled down below glass temperature. After dried, the tows are dragged to upper floor for cutting by Tension stand, which also guarantees the tows under tension evenness to feed Cutter in tangential direction of cutting reel. The tows are cut into fixing length of staple by adopting press cutting. After cutting, the cut fibers enter into baler chamber in gravity or through conveyor for baling, and then the bale is weighting, manual baling and labeling and then sent to the storage by fork lifter.